Project 2.04: Thermoplastic Composites by 3D Printing and Automated Manufacturing to Extend the Life

Thermoplastic Composites by 3D Printing and Automated Manufacturing to Extend the Life of Transportation Facilities

Project 2.04

Project Summary

This project aims to extend the life of transportation facilities by using 3D printed molds to manufacture thermoplastic composite molds that can be used as formworks for precast concrete. This project addresses the need to develop durable and cost-effective forms and tooling for precast concrete parts used in transportation.

Project 2.04 Final Report

Project Status:

Complete

Start Date:

01/01/2019

End Date:

12/31/2022

Project Cost:

$149,912

Project Type:

Base Funded

Agency ID:

69A3551847101

Sponsors:

Office of the Assistant Secretary for Research and Technology, University Transportation Centers Program, Department of Transportation

University of Maine, Maine Department of Transportation

Implementation of Research Outcomes:

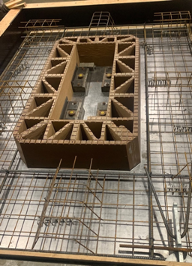

Large-scale railroad bridge ballast retainer formwork at American Concrete Ind. plant in Veazie, Maine.

3D printed form of at the Unistress Corp. precast concrete plant in Pittsfield, MA.

Impacts and Benefits of Implementation:

a. DOTs will be able to specify durable and cost-effective thermoplastic composites with optimized designs using large-scale 3D printings for precast concrete forms and tooling.

b. Optimized 3D printed forms will increase the longevity of precast concrete elements and parts.

Related Links:

- Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinforced PETG and PLA composites via annealing

- Elasto-Plastic Finite Element Modeling of Short Carbon Fiber Reinforced 3D Printed Acrylonitrile Butadiene Styrene Composites

- Large Scale 3D Printed Thermoplastic Composite Forms for Precast Concrete Structures

- Discrete event simulation thermal model for extrusion-based additive manufacturing of PLA and ABS

3D printing of Railroad Ballast Retainer formwork

Concrete placement in 3D printed formwork

On-Site Installment

Completed Installation