TIDC Research Team from UMaine Composites Center, UMaine Civil & Environmental Engineering and MaineDOT receive award for Best Paper by the Society of Plastics Engineers

Posted on 12/14/2021

Researchers from the University of Maine and Maine Department of Transportation received a Best Paper Award for research conducted in 3D printing thermoplastic polymer culvert diffuser for use in highway culvert rehabilitation. The award was presented to the group by the Society of Plastics Engineers Additive Manufacturing/3D Printing Chapter at the 2021 ANTEC Conference. The ANTEC conference consists largely of original, peer-reviewed technical presentations and sessions given by expert representatives from the largest industry segments.

Large-Scale Extrusion-Based 3D Printing for Highway Culvert Rehabilitation

Sunil Bhandari1,2 Roberto A. Lopez-Anido1,2 James Anderson1, Alexander Mann3

1Advanced Structures and Composites Center, University of Maine

2Department of Civil and Environmental Engineering, University of Maine

3Maine Department of TransportationABSTRACT

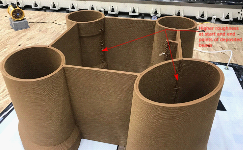

Large-scale extrusion-based 3D printing for highway culvert rehabilitation. A significant problem associated with repairing deteriorating highway culverts is the resultant lowered flow capacity. This can be mitigated by the use of culvert diffusers. Current culvert diffusers are made using fiberglass reinforced thermosetting epoxy polymers, which require custom made molds. This research work explores the use of large-scale 3D printed thermoplastic polymer composite to manufacture culvert diffusers. The research work shows that 3D printing technology reduces the manufacturing time as well as the cost of culvert diffusers. Large-scale 3D printing technology is well-suited for the manufacture of individualized culvert diffusers with unique geometrical designs without the need for molds. 3D printing technology is also capable of using different materials according to environmental requirements. The use of segmental manufacturing in conjunction with large-scale 3D printing enables the manufacturing of culvert diffusers larger than the build envelope of the 3D printer. Different post-processing techniques used for cutting, finishing, and joining the 3D printed segments are discussed.